Railway technology

Whether cabin modules for rail vehicles, mobile workshops for maintenance work or special containers for electrification and control - Gföllner develops technology solutions that are tailored to the special requirements of the rail sector.

Customized technology for rail projects

Whether vibration, temperature, EMC or fire protection in accordance with EN 45545: our user-oriented system units withstand extreme loads - reliably, durably and precisely tailored to your application.

Facts that impress:

- Dimensions: Individual modules up to 6 m wide, 25 m long, 4.5 m high

- Loads: up to 100 tons, statically optimized for heavy installations

- Extreme conditions: Heat, cold, vibration, sea air, dust exposure

- Standard compliance: EMC/fire protection/EX versions in accordance with current standards

- Mobility: Liftable, transportable - can be used worldwide

Applications

Railway technology

Advantages of railway technology

Everything from a single source

We analyze technical requirements, clarify standard specifications and develop a viable overall concept - in accordance with railroad standards and operator requirements.

Our engineering teams plan mechanics, HVAC, electrics and routing as a complete system - with 3D CAD, FEM calculation, shock/vibration simulation and EMC-compliant design for rail use.

From the load-bearing frame to the functional unit: we manufacture all structural elements in our own factory - welded in accordance with EN 15085 & ISO 3834, tested for dimensional accuracy, load-bearing capacity and suitability for use on railroads.

Our modules meet fire protection requirements in accordance with EN 45545, REI 30-120. High-quality paintwork (C3-C5M), hot-dip galvanizing and, on request, EX/EMC versions ensure functionality even under extreme environmental conditions.

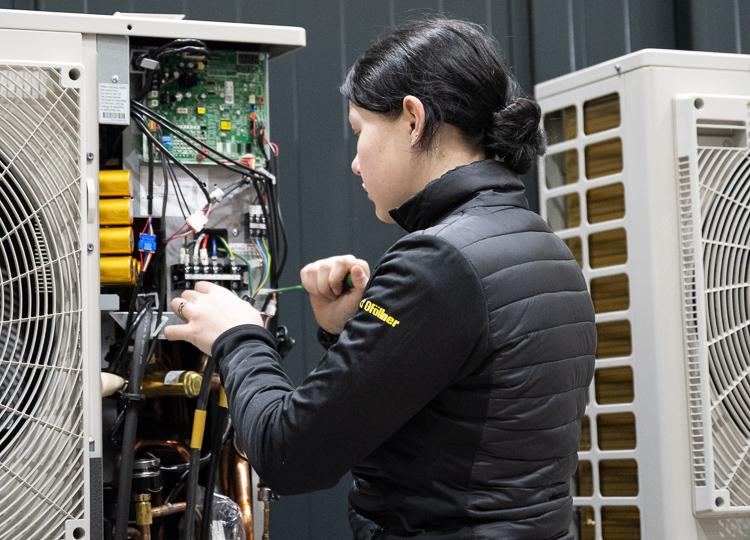

From the control cabinet to the air conditioning system: we integrate all systems in-house - coordinated, pre-wired, EMC-compliant and FAT-tested. Also for redundant HVAC, PLC controls and safety-related applications.

Every cabin or rail unit is comprehensively tested in the factory - mechanically, electrically and climatically. Our FAT protocols document functional safety, integration and standard-compliant design.

We take care of loading, transport coordination and, if required, accompany the final assembly - be it at the vehicle manufacturer, system integrator or end customer. Gföllner delivers - ready for operation, worldwide.

Services

We dimension cabin, module and functional structures according to railway-specific load cases - static, dynamic, seismic or shock-optimized (e.g. according to EN 12663).

Highlights:

- Dimensioning for dynamic railroad loads & vehicle connection

- Shock/vibration reserves for EN 61373, EN 12663

- Structural elements for roof superstructures, support frames or side mounting

- Integration into railroad carriages, tunnel vehicles or auxiliary trains

Our engineering combines rail standards, technical interfaces and system safety in an integrative approach - from CAD design to modular coupling.

Integrated functions:

- 3D design with collision check & vehicle adaptation

- HVAC/electrical layout tailored to space usage & interface plans

- EMC-compliant feed-throughs and rail-compliant routing

- Modularization for fast final assembly, hood/door systems, installation logic

From emergency power modules and HVAC controls to communication racks - we supply pre-assembled, tested electrical systems for cabins, carriage modules and operating vehicles.

Focus areas:

- NS/MS distributions, UPS, buffer solutions for catenary failure

- Control systems for HVAC, safety, communication

- Comprehensive EMC-compliant cabling for rail projects

- System testing & integration with control/vehicle systems

Railway-compatible HVAC systems - developed for extreme conditions in tunnel vehicles, workshop vehicles or communication modules.

Special features:

- Compact units for roof/wall mounting or split systems with internal evaporator

- Cooling capacity up to 135 kW - tailored to peak loads & ambient climate

- Filter technology, overpressure options, tropical kits for dust, oil mist, heat

- Pre-assembled & ready to control - tested for railroad operation & FAT-certified

Our cabins and superstructure modules are made from heavy-duty support frames - manufactured and tested in accordance with railroad standards and the highest safety standards.

Technical key points:

- Support frame for mobile and stationary railroad applications (e.g. auxiliary train auxiliary train, trailer)

- Welding technology in accordance with EN 15085, ISO 3834, EXC3 - incl. testing & documentation

- Sandwich panels, steel/aluminium constructions, mounting flanges or turntables

- Connection solutions for bogies, wagon frames or platforms

Reliable protection - inside and out - against environmental influences, corrosion and fire risks.

Scope of services:

- Fire galvanization in accordance with ISO 1461, C3-C5M coating for railroad environments

- Fire resistance REI 30 to REI 120 - for modules in accordance with EN 45545

- Internal coatings for clean room applications, moisture or EX zones

- EMC/sound insulation combinations, protective coatings for extreme applications

- Colouring and CI-compliant branding in accordance with customer requirements

The references speak for us!

Many national and international customers already rely on our expertise in products for mobile solutions.

Your contact partners

Downloads