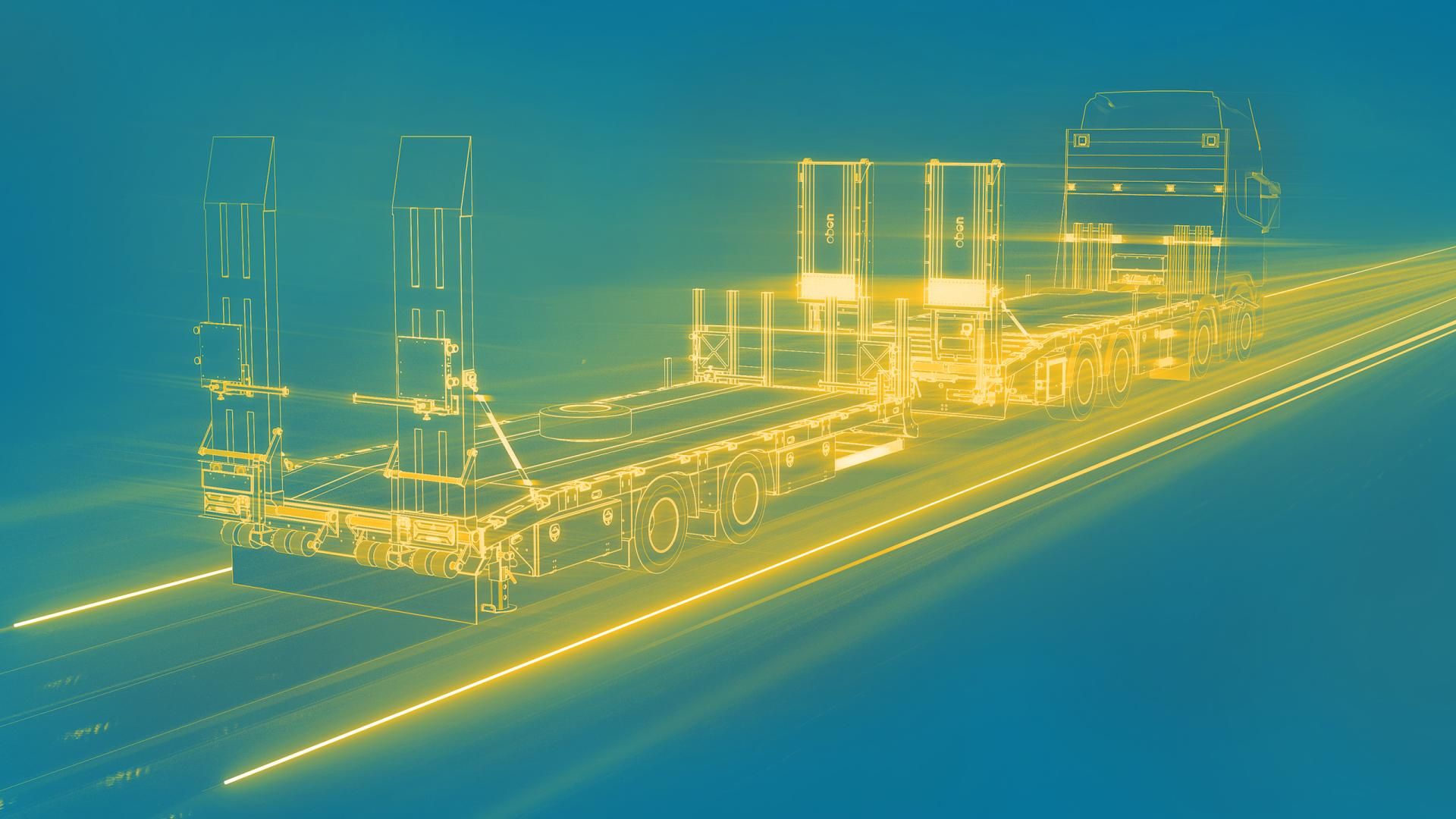

Vehicle construction

From precise detailed design to perfect finishing - we create vehicles that impress. Whether robust truck bodies, sophisticated trailer solutions or efficient swap systems: mobility is our element.

Mobility of today. Technology for tomorrow.

For decades, we have been implementing vehicle solutions for demanding transport tasks - from canvas bodies to ballast platforms and integrated loading crane solutions. Our superstructures have also long been used on electric vehicles. Gföllner is high-voltage certified and familiar with all current manufacturer guidelines.

Consulting, planning, production and service interlock seamlessly at Gföllner. Thanks to clear structures, in-house development and tested quality, ready-to-use vehicles are created - from a single source and to the point.

Industries in focus

Vehicles & cranes

Service & repair

We carry out repairs, maintenance and inspections in our workshop - quickly and reliably. So that your vehicles remain ready for use at all times.

Services

We combine technical expertise with precise implementation. From planning to commissioning, Gföllner provides you with everything from a single source—well thought out, coordinated, and ready for use.

From the initial idea to the finished vehicle: we provide individual advice, think application-specifically and plan in a solution-oriented way.

Our design department delivers precise 3D CAD models, including vehicle statics, axle load calculation and all relevant documents.

Our load-bearing backbone - literally. From the base frame to the outer structure, we rely on tested steel constructions in a high-precision design.

Technical key points:

- Support frame made of high-strength steel, dimensioned for mobile and stationary applications

- Welding technology in accordance with EN ISO 3834-2, EN 1090 EXC3 - incl. defence technology and railway standards

- . Defense technology and railroad standards

- CNC-controlled preparation, robotic welding, certified seam testing

- Sandwich panels, sheet metal constructions or lightweight construction depending on the project

- Connection details for foundation anchoring, container locking, crane eyes

So that your technology remains reliably protected - in the long term and under all climatic conditions.

Scope of services:

- Zinc plating in accordance with EN ISO 1461, coating in accordance with EN ISO 12944-5 (e.g. C3-C5M)

- Internal coating for damp, clean or aggressive atmospheres

- . C3-C5M)

- Internal coating for damp rooms, clean rooms or aggressive atmospheres

- Fire resistance REI 30 to REI 120 - wall, ceiling and door systems tested

- Ex-protected versions (e.g. ATEX zones), e.g. ATEX zones, e.g. ATEX zones). e.g. ATEX zones), EMC/sound insulation combinations possible

- Colour customization according to RAL - incl. company branding and lettering

- Powder coating

We integrate hydraulics, electrics and pneumatics - precisely tailored to the function, design and area of application.

From technical acceptance to official type approval - we take care of all the steps to ensure that your vehicle meets all legal requirements and is ready for immediate use.

We are also there for you after the handover - with repairs, maintenance and readily available spare parts.

Successful projects: Vehicles in use

Our products are in daily use throughout Europe - reliable, robust and precisely tailored to the respective requirements.

Your contact partners

Downloads

Marketplace